ENABLING THE TYRE INDUSTRY TO OPTIMIZE COSTs

Apart from the high complexity involved in the manufacturing of tyre and rubber parts, this industry faces additional challenges due to changing global standards, with regulations on environmental impacts, and consumer demand for high performance at a lower cost.

There is a need for adopting optimised production techniques in order to control the cost of production. Reducing wastages with best use of raw materials plays a major role in the competitive market positioning of a manufacturer.

The solutions that helps to get the maximum productivity in each stage of the manufacturing process with a centralised view to detect gaps in quality, regulatory and productivity goals will ensure that operational excellence is achieved.

Our tightly integrated IT-enabled solution that are modular and scalable caters to the tyre and rubber industry to achieve their business objectives.

Industry Expertise

INFORMATION SOLUTIONS

- Manufacturing Execution System (MES)

- Intelligent Weighing and Batching Solution (RMS)

- Intelligent Tyre Curing Software

- Statistical Process Control (SPC)

- Maintenance Management

- Digital Logbook

- Traceability (Barcode/RFID)

- FIFO, Inventory and Warehouse

- Utility / Energy Monitoring System

- Digital Twin & Historian

- Visual Inspection Systems

- Asset Management System

- Alarm Management and Analytics

- ERP-MES Data Exchange Layer (DEX)

CONTROL SOLUTIONS

- Mixer Control and Integration (PLC, SCADA)

- Batch Off Control System

- Mill and Blender Control System

- Banner Cutter Machine Control System

- Inner Line Calendar Control system

- Calendar Line Auxiliaries Control System

- Trench Conveyor Automation

- Trench Header Application

- Trench Recording and Monitoring

- PLC Timer Panel for Curing Press

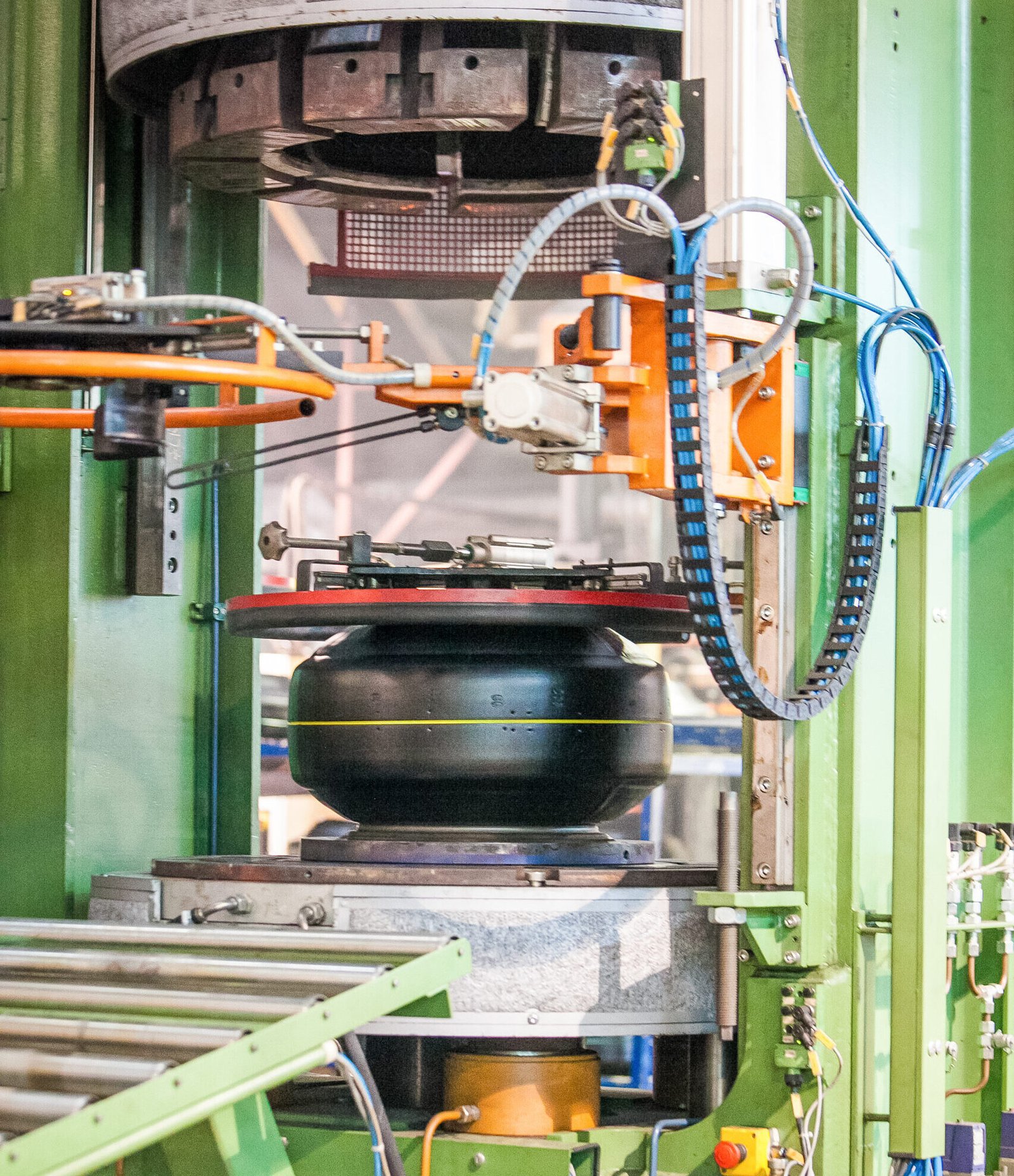

- Tire Curing Press Control System

- Boiler Control System and SCADA

- OTR Strip Winding Machine

- Tire Traffic Management

- Water Treatment - RO / ETP / STP / DM Control Systems

Our Esteemed Clients