EV BATTERY

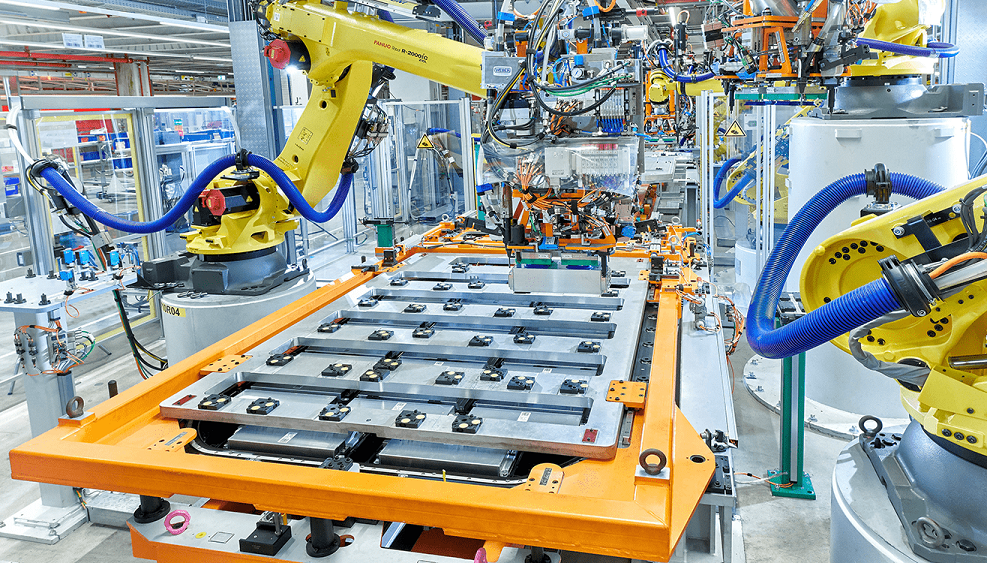

In the rapidly evolving landscape of electric vehicle (EV) batteries, meeting the diverse and demanding needs of consumers is crucial. Quality, performance, safety, and efficiency are paramount in this industry. To stay ahead, battery manufacturers must operate intelligently, optimizing their production processes to meet global safety standards while accelerating time-to-market.

Adaptable and agile manufacturing processes are essential for competitiveness and leadership in the EV battery market. Manufacturers must enhance efficiency in raw material sourcing and management, reducing production costs to remain competitive. Our solutions aim to boost yield by implementing cost-effective strategies, maximizing asset utilization, and leveraging IT-enabled tools to monitor productivity and compliance across the entire battery production chain, from raw materials to finished products.

Industry Expertise

INFORMATION SOLUTIONS

- Manufacturing Execution System (MES)

- Statistical Process Control (SPC)

- Maintenance Management

- Digital Logbook

- Traceability (Barcode/RFID)

- Utility / Energy Monitoring System

- Digital Twin & Historian

- Asset Management System

- Alarm Management and Analytics

CONTROL SOLUTIONS

- Current Monitoring System for Grid Casting Machine

- Lead Strip Control System

- Expander Press Control System

- Pasting Electrical Control System

- Control System for Heat Sealing and Leak Testing Machine

- Control System for Stacking Machine

- Lug Press Machine Control System

- Grid Casting Machine Control System

- Oxmaster Control System

- Lead Pot Machine Control System

- Ageing of Silo Management