-

Call Us

+91 73388 97775 - 276, 2nd Main Road, Nehru Nagar,

Kottivakkam, OMR, Chennai – 600096, India.

Successfully transforming the Industrial Manufacturing Business to achieve excellence for over 25 years!

276, 2nd Main Road, Nehru Nagar,

Kottivakkam, OMR, Chennai – 600096, India.

: 91 73388 97775

(Monday - Friday)

Industry 4.0 Lighthouse Certification by WEF

Industry 4.0 System Integrator > Tyre > Industry 4.0 Lighthouse Certification by WEFIntroduction

India’s tire manufacturing industry has long been a cornerstone of the nation’s economy, serving both domestic and international markets with distinction. Among the industry leaders stands a tire manufacturer renowned for its commitment to innovation and operational excellence. This manufacturer embarked on a groundbreaking project, setting a new standard for industry efficiency and sustainability. Notably, they were the first tire manufacturer in the world to be awarded Lighthouse Certification by the World Economic Forum (WEF).

Objective

The objectives of the project were multi-faceted:

1. Digitally manage their manufacturing operations: To streamline and enhance operational efficiency by digitalizing manufacturing processes and data management.

2. Horizontal and vertical integration: To achieve seamless integration across horizontal (truck-to-truck) and vertical (shop floor to top-floor) dimensions of the manufacturing operation.

3. Use advanced analytics for optimization: To leverage advanced analytics on collected data to drive continuous improvement and optimization across all aspects of production.

PROJECT OVERVIEW

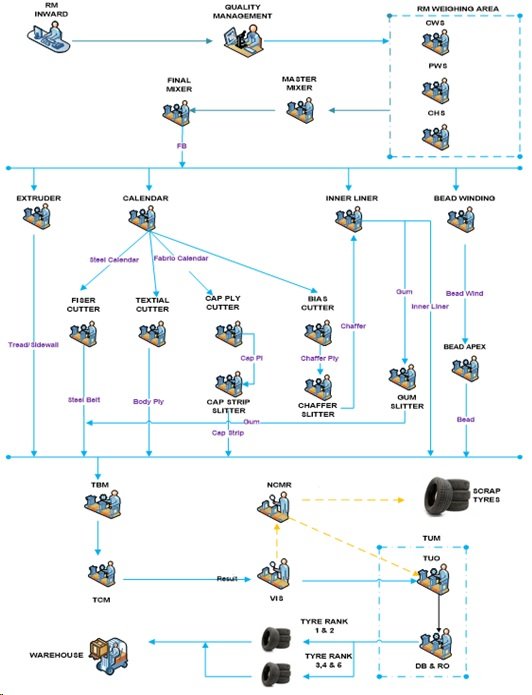

With an investment of $1 million USD, this tire manufacturer aimed to revolutionize operations across three plants situated within the same campus. The project spanned the entire production process, from raw material procurement to the dispatch of finished goods. It encompassed 10 distinct process areas, managing 374 assets, and interfaced with 16 different business units. A total of 176 use cases were identified and implemented to optimize operations and drive value across the manufacturing chain.

INTEGRATION STEPS

1. Digital Strategy: The project began with a comprehensive digital strategy, aligning technological initiatives with overarching business objectives.

2. Enterprise Architecture Design: Meticulous architecture design ensured seamless integration of digital solutions across the organization’s infrastructure.

3. Network Infrastructure: Robust network infrastructure supported the connectivity requirements, enabling efficient data exchange and communication.

4. Smart Thing Connectivity: Implementation of smart thing connectivity facilitated real-time monitoring and control, enhancing operational visibility and agility.

5. Homogenous MIS Integration: Integrated Management Information Systems (MIS) standardized data management practices, enabling accurate decision-making.

6. Heterogeneous Feature Development: Tailored features addressed diverse operational needs, ensuring efficiency across manufacturing processes.

7. Unit Testing: Rigorous unit testing validated functionality and performance before broader integration.

8. Production Testing: Comprehensive production testing identified and resolved operational bottlenecks in real-world scenarios.

9. Training: Extensive training programs ensured smooth transition and adoption of new tools and processes.

Digital Transformation Results

Digital transformation of their manufacturing process has provided them with the following results that have collectively improved their overall production enabling them to produce more with less.

Some of the tangible results are:

1. Elimination of paper in the shop floor, leading to a complete digitization of all data minimizing operator inputs

2. Reduced cycle time by 20%

3. Reduced steam consumption by 20% saving energy costs

4. Reduced compressed air consumption by 20%

5. Reduced total scrap by 46%

6. Improved on time in full (OTIF) deliveries to customers by 29%

7. Increased throughput of upstream mixing process by 28% by reducing setup time

8. Increased factory throughput by 25%

9. Increased Overall Equipment Effectiveness (OEE) to over 80%

10. Digitized over 330+ logbooks, resulting in man efforts reduction by 65% increasing data accuracy.

ROI Calculation

Data for Return on Investment (ROI) calculation was collected at multiple intervals post-implementation, including 90 days, 6 months, and 18 months. The project yielded remarkable results, with a total ROI of $50 million USD realized from increased production capacity, enhanced Overall Equipment Effectiveness (OEE), and reduced waste.

Total investment: $1,000,000 USD Total assets: 374

Cost per Asset: $2,674 USD (Total Investment / Total Assets)

ROI per Asset: $133,689 USD (Total ROI / Total Assets)

The cost per asset analysis reveals that the investment in digital transformation averaged to approximately $2,674 per asset. Considering the substantial return on investment per asset, which amounts to $133,689, it is evident that the digital transformation initiative significantly increased the value derived from each asset within the manufacturing plants.

This underscores the efficiency and effectiveness of the digital solutions implemented across the organization, resulting in substantial improvements in operational performance and overall profitability.

CONCLUSION

Through strategic investment and unwavering dedication to innovation, this tire manufacturer not only transformed its operations but also set a global benchmark for excellence. Being the first tire manufacturer worldwide to achieve Lighthouse Certification by the World Economic Forum (WEF) underscores their commitment to sustainability and operational innovation.

This case study exemplifies the pivotal role of forward-thinking strategies in driving industry leadership and fostering sustainable growth in today’s rapidly evolving business landscape.